Learning from 3D Print Errors

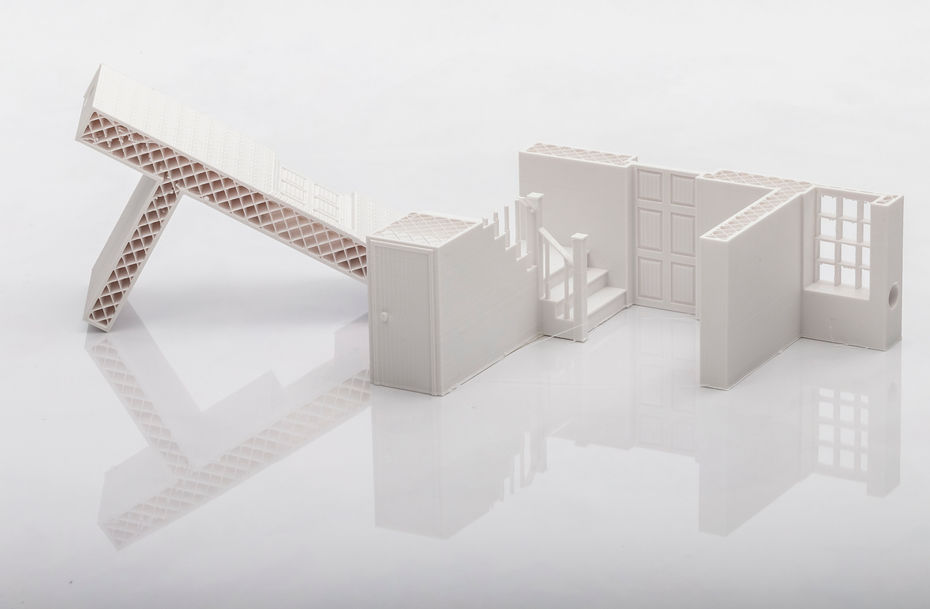

The 3D printer presented unexpected challenges. Clogged extruders, cooling issues causing model warping, and problematic support material forced me to think of creative solutions. Through trial and error, we devised ways to maintain the heat and stop the warping. For example, wrapping the printer with Saran Wrap held the heat in long enough for some successful prints. However, it soon became clear that printing the house’s finer details required a more advanced 3D printer. Our new 3D printer (check out the video here) solved many of these problematic issues. See below for images of some prints that didn't go as planned.

Window printing errors

Fine details, like the railing support structures, were difficult to produce

Joining pins, which allowed us to assemble and disassemble the model, were the weak points. They frequently snapped and broke inside the model. The solution was embedding magnets instead (see the magnets in action here).

02

Harris

Agnew